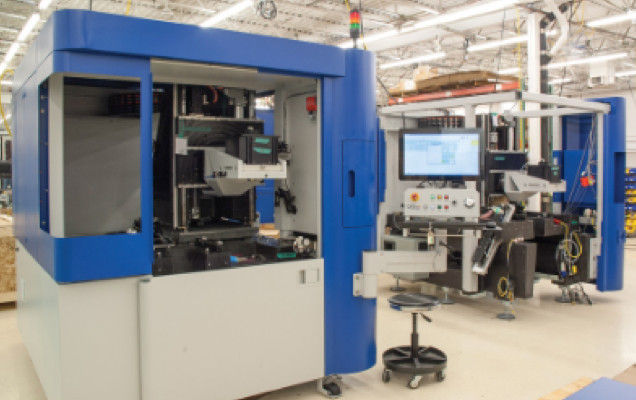

PEKO is an AS9100 and ITAR certified contract manufacturer of large, fabricated structures, mechanical assemblies, and precision components for military and DoD prime contractors.

PEKO is a well-suited supplier of highly accurate defect free parts and assemblies that comply with critical DOD specifications, government regulations, and Tier 1 contractor standards. Whether it’s navigating Engineering & Manufacturing Development (EMD) or managing Low-Rate Initial Production (LRIP) and Full Rate Production (FRP), we’ve outfitted ourselves with the capabilities to seamlessly support your program at any stage of the product lifecycle.

Peko is a terrific company, and we can see why that is: you have excellent folks leading the way. Most companies like to say they are on the cutting edge, but Peko really is, and it was impressive to see in person. You all are doing a great job.

– Special Agent, US Dept of Homeland Security

We take great pride in our role supporting defense contractors in the creation of high-tech systems and equipment that help advance our national security and defense operations. Our defense contract manufacturing service offers a comprehensive solution for producing high precision components, critical assemblies, major mechanical structures, and electromechanical subsystems tailored to meet the exacting requirements of our defense industry clients.

Interested to see how we can help

with your manufacturing process?

Book your meeting today.

Talk to us:

Write to us:

Trying to figure out how your company will make your medical product can be a seamless process if you work with a qualified Contract Manufacturer. In this free guide, we offer tips on what to look for when you begin your search for a contract manufacturer to be the right fit for you and your company.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus