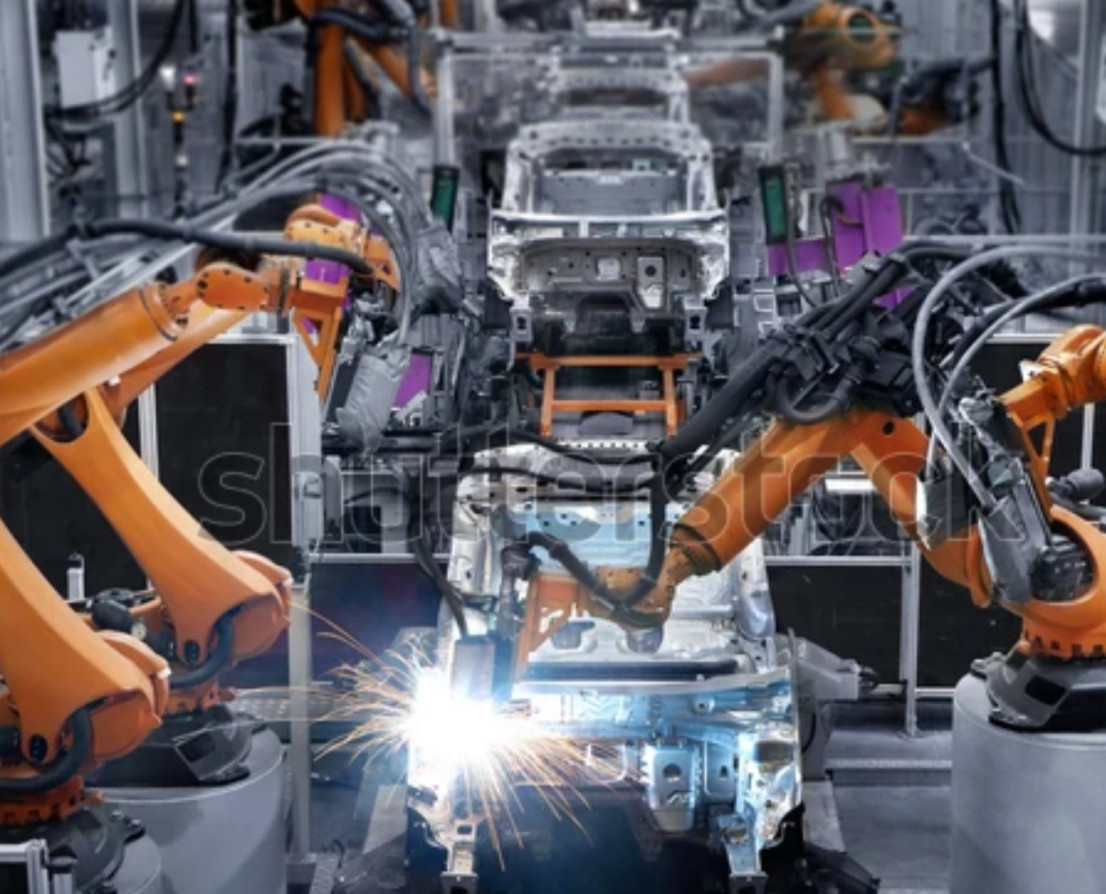

Develop & Build Your Machinery & Equipment in a Seamless Process

PEKO Precision

Turning your highly sophisticated

manufacturing plans into

reality starts now

Discover what makes PEKO Precision the most reliable, capable manufacturing partner

to help you deliver every stage needed for the manufacturing production lifecycle.

Description to some text here.

Description to some text here.

Description to some text here.

Description to some text here.

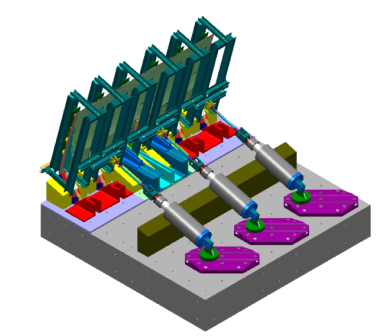

Let’s set the foundation for success right from the start. As soon as we initiate a contract, we’ll work toward creating a successful manufacturing plan

to build your machinery, equipment, and instrumentation in our state-of-the-art facilities.

Our engineers will work directly with your team

to understand your specifications, requirements,

and end-users, and compile your existing prints, BOMs, and tribal knowledge. Once we have all the product and manufacturing knowledge identified, we develop a manufacturing process that achieves the quality, lead time, and performance that our customer desires.

We understand how critical program management is for success, which is why we provide a program manager for each program to provide a single point of contact throughout the duration of the project. Program managers, or PMs, provide leadership for each program, with access to all PEKO’s

resources through senior management on

a daily, weekly, and monthly basis. Program

teams are assigned by function and are

dependent upon the type of industry.

This allows for the utilization of specific team members with knowledge and expertise

unique to industry-specific requirements.

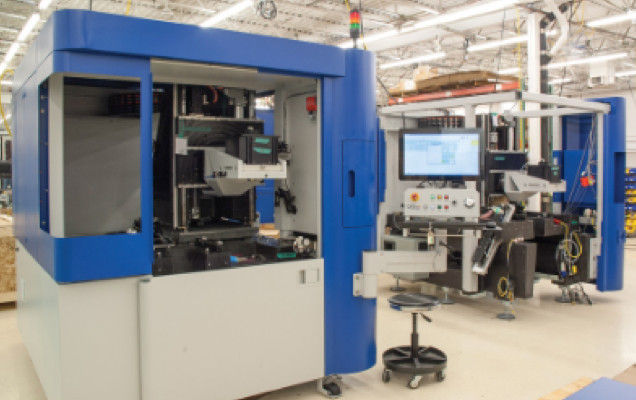

We perform all our contract manufacturing services in a comprehensive setting that preserves and protects your intellectual property, or IP. PEKO does not have–nor do we desire to have–any products of our own and we provide NDAs for every program to protect our customer’s proprietary information.

At PEKO, we’re always working with an OEM to “define good.” This contract

manufacturing philosophy describes our ability to take a piece of sophisticated

machinery or equipment, and formally agree upon all the attributes that must be

satisfied before the product can be shipped. This is called factory acceptance

testing, or FAT. Program stakeholders from both the OEM and CM are involved

in this critical portion of the onboarding process.

Trying to figure out how your company will make your medical product can be a seamless process if you work with a qualified Contract Manufacturer. In this free guide, we offer tips on what to look for when you begin your search for a contract manufacturer to be the right fit for you and your company.

– Metal Powder Coating

– Wet Painting

– Metal Silk Screening

Learn More

– Metal Powder Coating

– Wet Painting

– Metal Silk Screening

Learn More

– Metal Powder Coating

– Wet Painting

– Metal Silk Screening

Learn More

– Metal Powder Coating

– Wet Painting

– Metal Silk Screening

Learn More

Code Assistance.

Code Assistance.

Code Assistance.

Code Assistance.

Code Assistance.

Code Assistance.

Interested to see how we can help

with your manufacturing process?

Book your meeting today.

Talk to us:

Write to us:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus